In this piece, we'll talk about why a Programmable Logic Controller (PLC) is better than a Personal Computer (PC) in industrial control systems and automation.

Up until the last few years, the PLC was by far the most popular, but the PC is starting to look like the Controller of choice. We'll give you more information about that later.

Let's start at the beginning...

What are a PLC and a PC?

Since the 1970s, PLCs have been around. The first PLCs only had one computer. They were made to replace decision-making, hard-wired relays, and timers with a software program made by the user that makes the necessary choices.

All of the switches, sensors, and motors in the field that needed to be watched and controlled were wired to add-on modules that were linked to the microprocessor module.

It didn't take long for the PLC to change and add modules that could handle analog processes and processes that were controlled by PID.

Also around for a long time is the PC. In the 1980s, the word "Personal Computer" was made up because the device was meant to be used by only one person at a time.

Then came the laptop, the tablet, and now the smartphone, all of which could do what a PC could do.

The PC was not made to be used in automation and management at first.

Okay… So, what are some of the main ways in which a PLC and a PC are different?

What's different about a PLC and a PC?

A PLC has a special computer and an Operating System that no other machine has.

An Operating System, like Microsoft Windows, Mac OS, or Chrome OS, is what makes a PC work. One could say that a computer with a MAC OS or Chrome OS is not a PC from a technical point of view.

Programming tools like Rockwell Studio 5000 and Siemens TIA Portal are used to set up a PLC. This private software is used to write programs in one of the standard languages for PLCs set by the IEC 61131-3.

The fact that the private software is on a PC is interesting. The control program is then put on the PC and then sent to the PLC to be run.

Usually, structured text and higher-level computer languages like C++ are used to code PCs.

Most of the time, a PC is used as a host for commercial software like Microsoft Office, which is used for word writing and accounting.

The way a program is run is a big difference between a PLC and a PC.

PC software programs are usually driven by events, while PLC programs are generally based on scans.

All right...

What is better about a PLC than a PC?

Why a PLC is better than a PC

A PLC was built to hurt. A PLC is built so that it can work reliably in very rough manufacturing settings. It can stand up to heat, cold, dust, and other bad things in the environment.

A PC was made to sit on a desk or in your lap in an eco-friendly setting.

A PLC was made to be easy to write and figure out what's wrong. Since the operating system of a PLC is unique, it can't be attacked by viruses or hackers.

A PC is very open to cyberattacks and bugs.

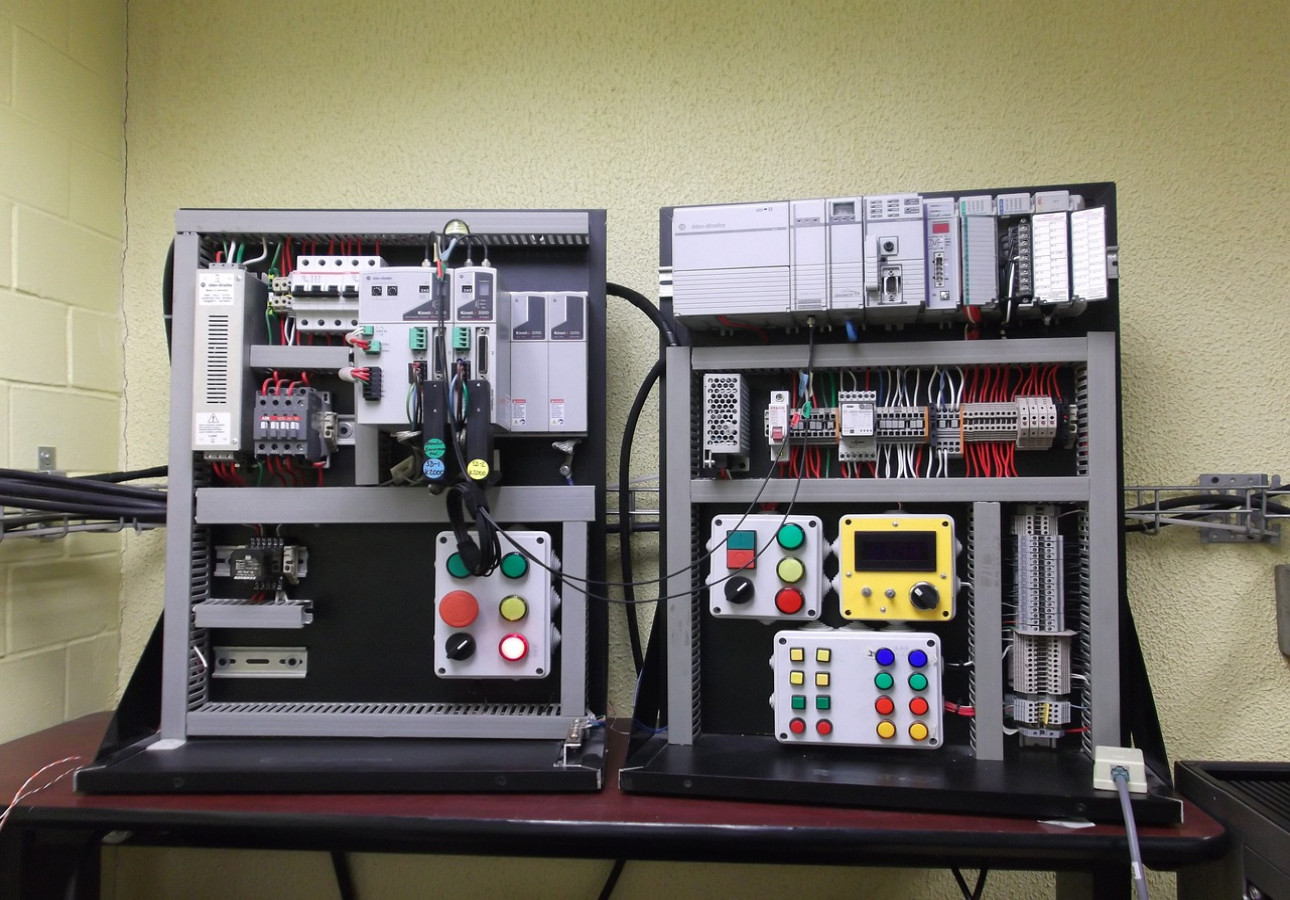

A PLC is made so that it is easy to add on to. If you want to work with more field devices, you can add Input/Output Modules.

When it comes to expansion modules, PLCs can easily use modules that help with industrial communication standards like Profibus, CAN bus, Modbus, Ethernet/IP, and others.

A PC can be made bigger, but it's not easy to do.

PLCs' uses

PLC cabinets are used in almost every business, from oil plants to sawmills.

PLCs are also used in heavy mobile tools like a FRAC Truck or a Hydraulic Mining Shovel.

Allen-Bradley, Omron, Siemens, Phoenix Contact, and Schneider are some of the best PLC makers. There are a lot more, and it seems like the list gets longer every year.

At the beginning of this piece, we said that until the last few years, the PLC was the clear winner, but now the PC is starting to win out.

Let's find out more about that sentence. An Industrial PC is the new kid on the block.

It has an Operating System that lets it run programs and apps that PLCs can't. So, unlike the PLC, this new Industrial PC can do more than just handle.

The Industrial PC is different from a regular PC because of how it is made.

Industrial-grade PCs are made to work in tough conditions and high temperatures, and they can also handle shocks and vibrations.

Programming is a big reason why the Industrial PC is better than the PLC. A Windows operating system, which almost everyone knows, is used on an Industrial PC.

Programmers for traditional PLCs know IEC 61131-3 languages like Ladder Diagram and Function Block.

Higher-level languages like C++ can be used by a new breed of IT pros to write control programs for the Industrial PC.

Summary

Ok, let's go over what we've talked about in this piece...

PLCs were made so that a user-created software program could take the place of decision-making, hard-wired switches, and timers.

A PLC has its own computer and its own way of running software.

If you want to leave a comment, please log in first.

Comments